UL 325 Safety Standards for Automated Gate Operators

HySecurity Gate openers are a secure and convenient way to maintain access control for residential, commercial, and even industrial properties. Utilizing mechanics and electricity, these gate systems allow for automatic gate operation that provides effortless entry and exit. However, these automatic gate operators do pose some safety risks as they are powerful pieces of machinery that involve many moving parts. Because of this, safety standards have been set in place to prevent potential entrapment. These safety regulations are crucial for protecting people, vehicles, and animals, as well as for legal liability purposes. Ignoring these standards can lead to a high risk of serious injury or even death if entrapment were to occur. We'll walk you through the core pillars of gate opener safety and how they coincide with HySecurity automatic gate systems.

UL325 Safety Standards Overview

The UL 325 Safety Standards are one of the core safety standards that has been set to properly address the safety concerns and requirements needed for the automatic operation of all garage doors, vehicular gates, draperies, exterior awnings, louvers, windows and other opening and closing appliances rated 600 V or less. Created by leading industry personnel alongside Underwriters Laboratories (UL), these regulations were written with a primary goal of evaluating products with the consideration of public safety.

All gate operators manufactured on or after August 1st, 2018 must meet or exceed the most up-to-date standards for safety set forth by the 7th Edition of UL 325.

UL325 Key Factors:

- Gate Operator Types & Classes

- Each Operator Type's Defined Entrapment Zones

- Types of Entrapment Protection Devices

- Minimum Quantity of Entrapment Protection Devices

Gate Operator Classes According To UL325

The latest revision to the UL 325 standard classifies the different types of gate systems. The goal in classifying these gate systems and their intended uses is to allow for more clarity when adhering to safety standards. Each class has required types of obstruction sensing devices. The classes are as follows:

Class I - Residential Vehicular Gate Operator

A vehicular gate operator or system intended for use in garages or parking areas associated with a residence of one to four single families.

Class II - Commercial/General Access Vehicular Gate Operator

A vehicular gate operator or system intended for use in a commercial location or building such as a multi-family housing unit (five or more single-family units), hotels, garages, retail store, or other buildings accessible by or servicing the general public.

Class III - Industrial/Limited Access Vehicular Gate Operator

A vehicular gate operator or system intended for use in an industrial location or building such as a factory or loading dock area or other locations not accessible by or intended to service the general public.

Class IV - Restricted Access Vehicular Gate Operator

A vehicular gate operator or system intended for use in a guarded industrial location or building such as an airport security area or other restricted access locations not servicing the general public, in which authorized access is prevented via supervision by security personnel.

Commercial & Industrial Gate Operators (Classes II-IV) Increased Risks

Following these safety standards are incredibly important for every gate operator setting or UL325 Class, but it's crucial to recognize the increased risks that come with a gate operation at a commercial or industrial property and why adhering to regulations is a necessity for these high-traffic locations. Non-Compliance is not just a technical issue as it can subject businesses to costly lawsuits, code violations, fines, or even denied permits or inspections for new installers.

Elevated Risks:

- Heavier Vehicular Traffic: Potentially including delivery trucks, semi-trucks, buses, specialized equipment, construction vehicles, etc.

- More Frequent Gate Cycles: Dependent on location but some utilize hundreds of operations per day.

- Wide Range of Users: Some sites have different personnel consistently coming in and out, not all of whom may be familiar with automatic gates.

These increased risks for commercial or industrial gate openers make following the correct safety regulations a very high priority, but it also raises the importance of choosing the proper gate opener for the application or setting it will be used for. HySecurity specializes in UL325 compliant commercial and industrial gate operating systems for large locations that may require extra security.

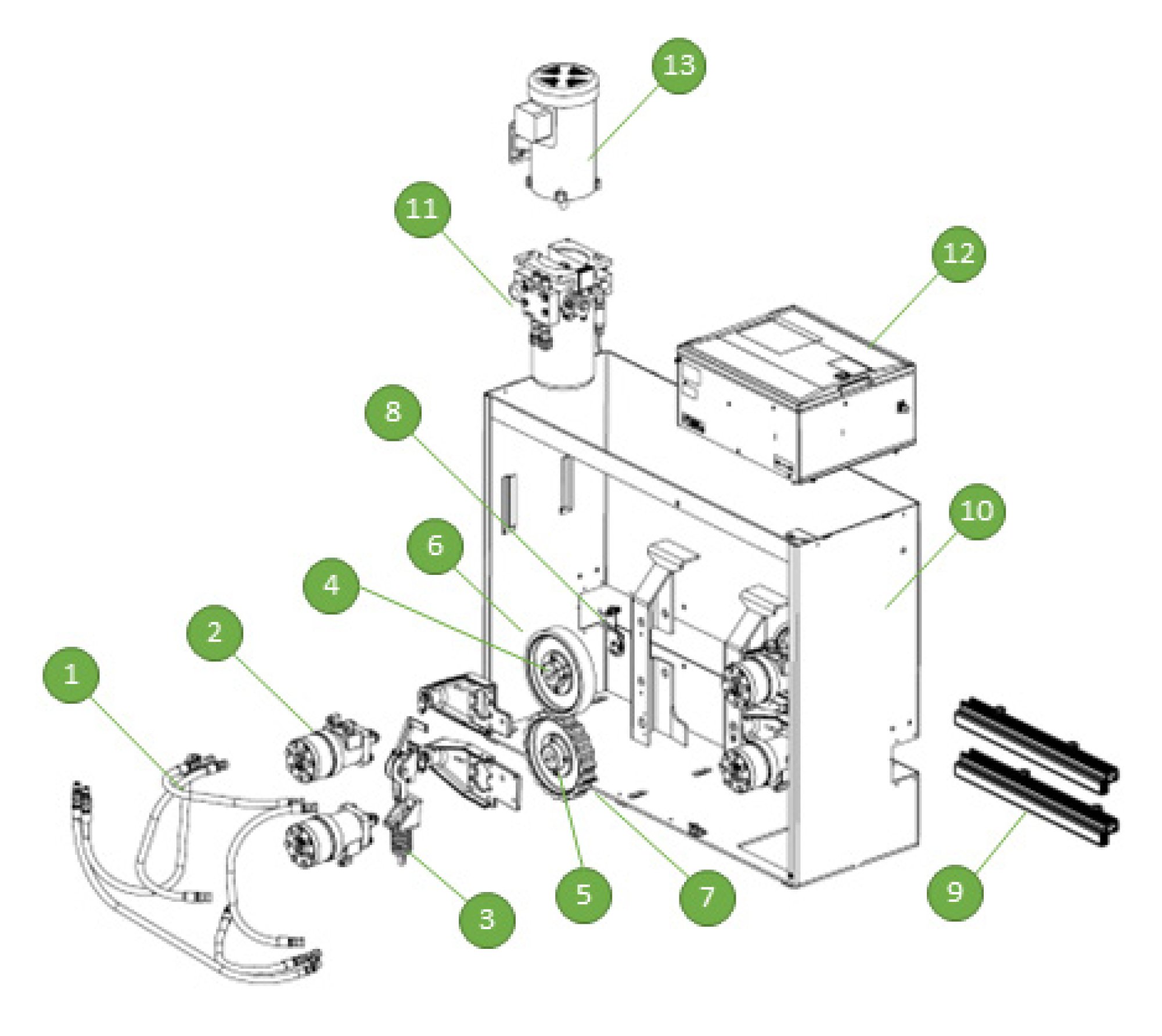

UL325 Compliant Commercial, Industrial, And Maximum Security Gate Openers By HySecurity

Types Of Gate Operator Systems

UL325 also classifies the different types of gate openers into categories based on the motion of the system and how it operates. The reason for this is because different types of gate openers have different risks based on the movement and force it is exerting. It's important to familiarize yourself with the different classifications of gate openers before determining which protection devices you are required to have and what areas around your gate opener pose the greatest risks for entrapment.

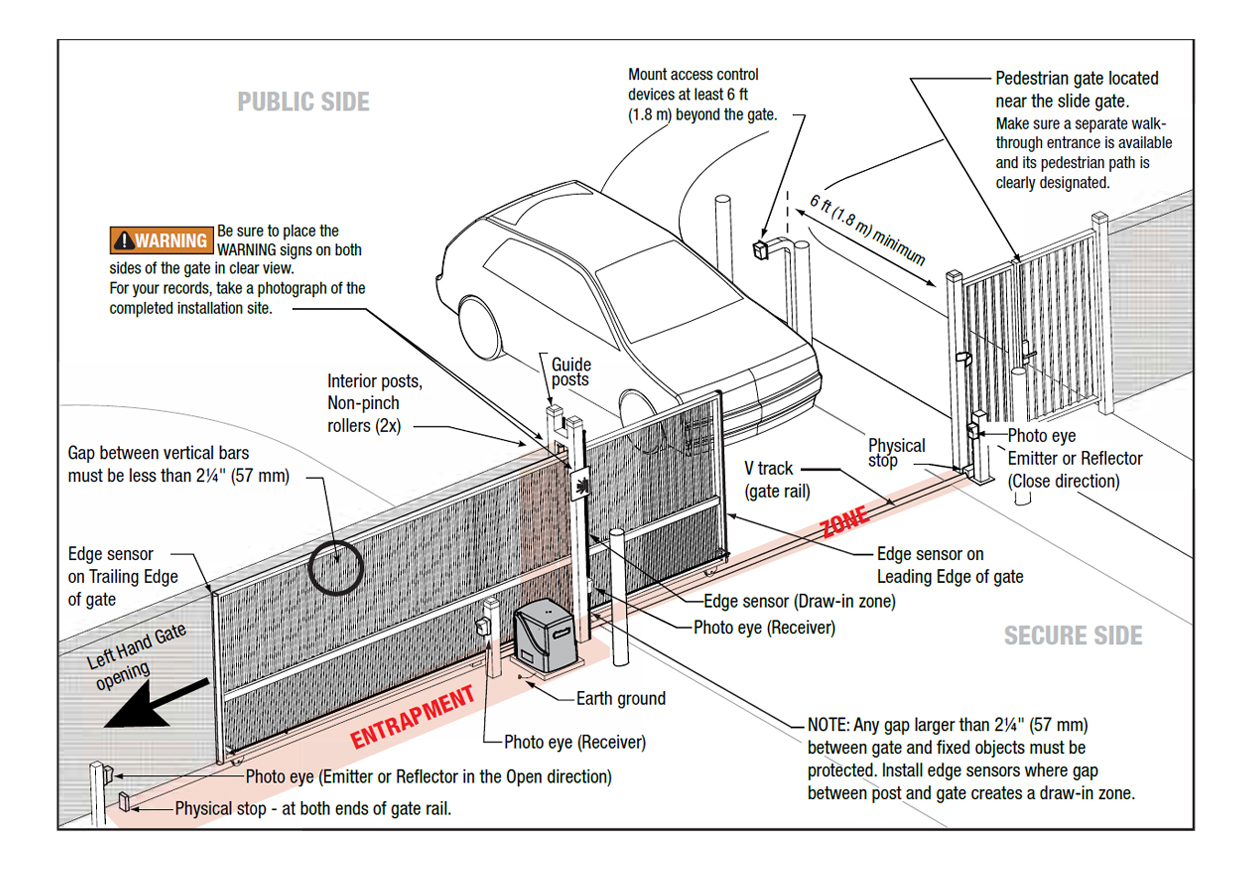

Horizontal Slide Gate Operators

These gates slide horizontally across an opening, typically along a track or cantilever system. Common in commercial and industrial settings due to their space efficiency and security.

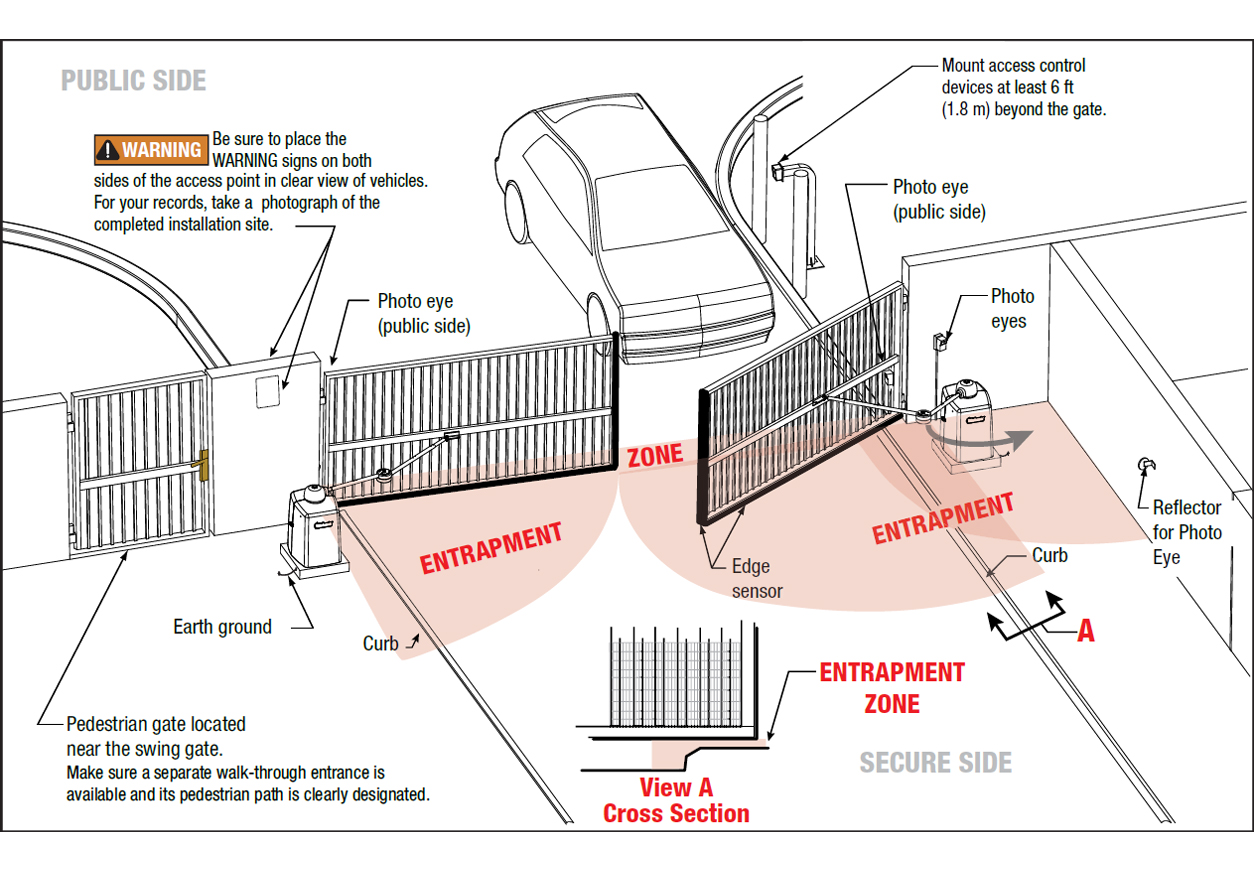

Swing Gate Operators

Swing gates open inward or outward like a traditional door, pivoting on hinges. They're often used in residential or light commercial applications, but require clear space to operate safely.

Vertical Lift Gate Operators

These gates move straight up vertically, usually supported by side columns or structures. They're ideal for locations with limited lateral space and high-security needs, like loading docks or industrial sites.

Vertical Pivot Gate Operators

Pivot gates rotate vertically upward from one side, much like a large lever. They're fast-operating and space-saving, making them well-suited for high-security or high-traffic applications.

Vehicular Barrier Arm Gate Operators

Often seen at parking garages and toll booths, these gates use a horizontal arm that raises and lowers to control vehicle access. While they deter entry, they don't fully block a vehicle path, so they're mainly used for traffic control rather than physical security.

Entrapment Zones

An entrapment zone is any area in or around an automated gate where a person or object could become trapped, pinned, or crushed during the gate's movement. UL 325 requires that these zones be identified, addressed, and protected to reduce the risk of serious injury or death. Entrapment zones vary depending on the type of gate and the motion it goes through during operation. Common locations include:

- Any area between a moving gate and a stationary object

- The leading edge of a sliding or swinging gate as it moves towards a fixed object

- Pinch points where gate components could catch clothing or limbs

- Areas within the gate path that may trap someone against a nearby structure

Swing Gate Opener Entrapment Zones

Slide Gate Opener Entrapment Zones

Entrapment Protection Devices

Due to the dangers that the entrapment zones pose, UL325 requires a minimum number of entrapment protection devices per entrapment zone. For most gate operators, a minimum of 2 different types of protection devices are required in each direction of travel, but the requirement does depend on the type of gate opener system. These devices work in different ways, but all serve the same safety goal of preventing a gate from closing or trapping a person, animal, or vehicle. The charts below describe each type of entrapment protection device and outline what types of devices are applicable and how many are required for each type of gate opener.

| Device Classification | Type of Device | Explanation |

|---|---|---|

| Type A | Inherent Entrapments Protection System | A feature of the gate operator that is directly built into the system that senses resistance or obstruction during movement. |

| Type B1 | Non-Contact Sensor | A sensor that uses an infrared or laser beam to detect obstructions without contact, such as a photo eye. |

| Type B2 | Contact Sensor | A pressure-sensitive device typically mounted on the gate's leading edge or post that triggers a reversal when contact is made. |

| Type C | Inherent Force Limiting, Inherent Adjustable Clutch or Inherent Pressure Relief Device | A variation of Type A, but specifically refers to inherent force limiting, adjustable clutches, or inherent pressure relief devices. |

| Type D | Actuating Device | A control device (like a push-button or keyed switch) that only operates the gate while continuously pressed. |

| Gate Type | Entrapment Protection Device Types Allowed | Minimum Protection Devices For Opening | Minimum Protection Devices For Closing |

|---|---|---|---|

| Horizontal Slide Gate | A, B1, B2, or D | 2 | 2 |

| Horizontal Swing Gate | A, B1, B2, C, or D | 2 | 2 |

| Vertical Pivot Gate | A, B1, B2, or D | 2 | 2 |

| Vertical Lift Gate | A, B1, B2, or D | 1 | 2 |

| Vehicular Barrier Arm Gates | A, B1, B2, C, or D | 2 | 2 |

*For a horizontal swing gate operator, at least two independent entrapment protection means are required in each direction of travel. Except, if there is no entrapment zone in one direction of travel, only one means of entrapment protection is required in that direction of travel; however, the other direction must have two independent entrapment protection means.

UL325 Compliant Safety Devices By HySecurity

HySecurity offers many different entrapment protection devices that are compatible with HySecurity gate operators including photo eyes and safety edges. Whether you're installing or purchasing a residential, commercial, or industrial gate opener, choosing the proper safety devices that work well with your specific operator is crucial. Below we have linked some of HySecurity's entrapment protection devices, but keep in mind that most installations require two DIFFERENT device types per entrapment zone

ASTM F2200 Safety Standards Overview

The ASTM F2200 governs the construction of the gates that are intended to be automatic gates. It is very similar to UL325 and the two go hand in hand, but they still serve different purposes. While UL325 focuses on protecting people from hazards related to the operator, the ASTM F2200 focuses on safety related to the gate's physical structure and design.

ASTM F2200 Requires Automatic Gates To Have The Following

- Guard Posts

- Protective Screen Mesh

- Covers For All Exposed Rollers

- Swing gates must not have any protrusions on the bottom of the gate

- Gates must be prevented from falling over if disconnected from the gate opener

- Swing gates with potential entrapment zones of greater than 4" to less than 16" must be protected

- Slide gates and the adjacent fence must not allow a 2 1/4" sphere to pass through up 48" from the ground

ASTM F2200 Requirements For Slide Gates:

- All exposed weight bearing rollers and pinch points that exist in less than 8 ft above grade must have covers.

- Gate must have fall over protection to prevent the gate from falling when it is detached from supporting hardware.

- The physical gate stops to avoid over-travel in both directions.

- Proper adjustment of the inherent sensing system.

- No protrusions along the bottom of the gate.

- Protective screen mesh to guard openings from the gate's base support to a minimum height of 6 ft above the ground. This must prevent a sphere of 2.25 inches from passing under or through any opening in the gate or adjacent fence (the portion covered in the gate's open position).

ASTM F2200 Requirements for Swing Gates:

- Swing Gates used for vehicular traffic, operators must be installed

- Pedestrians must be directed to a separate entrance and exit

- The area of the gate must be designed so that people do not come in contact with it while it is in motion

- Signage to warn pedestrians to stay clear of the gate's path should be posted and be clearly visible

- Proper promotion of the separate pedestrian entrance and exit.

- No protrusions along the bottom of the gate.

- Fall over protection to prevent the gate from falling when the gate is detached from supporting hardware.

Professional Installation

If a professional is installing your gate opener, he or she should provide you with a safe gate operating system. To ensure this safety, and to comply with the manufacturer's installation instructions and industry safety standards, your installer should present you with different options of certain safety devices that they feel are necessary to ensure a safe gate system. We STRONGLY suggest that you discuss these options with your installer and heed his or her recommendations regarding entrapment prevention devices and gate construction criteria. You should also refer to the manufacturer's installation manual for more information on the safety provisions and requirements of your particular vehicular gate system.

This Safety Checklist serves as a critical tool for installers and maintenance personnel to ensure gate systems are operating safely and in full compliance with UL 325 and ASTM F2200 standards. It guides users through verifying that all required safety devices, such as photo eyes, edge sensors, and alarms, are properly installed, connected, and tested. The checklist also emphasizes the importance of correct gate construction, secure wiring, proper signage, and regular functional testing of all entrapment protection systems. Following this checklist helps reduce the risk of injury, enhances system reliability, and supports liability protection for property owners and operators.

Gate Installation Safety ChecklistGate Opener Safety 101 & A Guide To Safety Accessories Video

As a supplement to the information that was featured in this article, the following video created by the DF Supply Family provides an easy-to-follow visual walkthrough of gate opener safety standards, entrapment protection devices, and additional safety accessories. Please note that while the video is an excellent source for gate opener safety information, the accessories that are shown may not be compatible with HySecurity Gate Openers.

HySecurity gate operators offer a powerful and efficient solution for managing access, but their effectiveness depends on thoughtful installation and strict adherence to established safety standards. With the increased risks that come with automated gate systems, especially in commercial and industrial environments, it's essential to follow UL 325 and ASTM F2200 guidelines to protect people, property, and your liability.

Choosing the right gate operator and safety accessories isn't always straightforward, which is why our team of trained professionals is available to answer your questions and help you find the best solution for your specific application. Please feel free to reach out so we can point you in the right direction for all of your gate operator needs!

Contact Us